Author: Argelith

Fully vitrified ceramic tile is literally born in fire.

When the heat is on, does your floor show up strong or start to soften?

Temperature is often overlooked when listing requirements for a facility’s floor. You know what you need in terms of thickness, toughness, and resistance. But it’s easy to forget how radical temperature changes can impact their environment.

Take a commercial kitchen for example. The owner, looking for an affordable option that is easy to clean, slip resistant, and water resistant, might choose an epoxy coating.

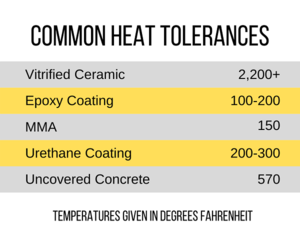

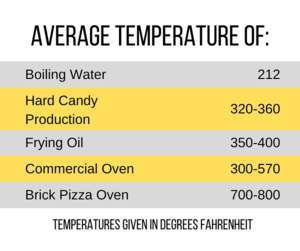

Everything seems fine until oil spatters from an overfilled fryer onto the floor. Frying oil is typically between 350 and 400 degrees Fahrenheit. When it hits an epoxy coating that softens between 100 and 200 degrees Fahrenheit, each drop of hot oil leaves a scar. This pitting is a common problem that is especially regrettable because it is so avoidable.

Know your needs

When figuring the temperature needs for your facility, don’t look only at the overall ambient temperature. What temperatures will localized sections of the floor encounter?

We’ve already established hot oil is in the neighborhood of 400 degrees. A commercial baking oven can give off radiant heat as high as 500 degrees – and a brick pizza oven gets as hot as 800 degrees.

Even boiling water, at 212 degrees Fahrenheit, is too hot for frequent or heavy exposure to materials like MMA coatings, many of which are only resistant up to around 150 degrees.

Your room may be in the range of 75 to 85 degrees Fahrenheit, but to avoid localized degradation of your building materials, take local zone temperatures into account.

How much heat can ceramic tile withstand?

Fully vitrified ceramic tile, like that made by Argelith, is created in kilns burning at around 2,200 degrees Fahrenheit, so we can safely assume it is resistant to temperatures at least that high.

Ceramic tile is inherently different from industrial coatings. It is a solid block, not a poured or painted on covering. It is made of natural, inorganic materials – mostly minerals and clays. In the event of a fire, ceramic will not burn.

Fully vitrified tile is literally born in fire. The long, hot firing strengthens and hardens the ceramic. When fully vitrified ceramic tile encounters high temperatures, it absorbs the heat slowly throughout its thick, uniform body. When the heat source is removed, the tile releases the heat equally slowly.

This slow, even heating and cooling not only means ceramic tile is stable at high temperatures, it also protects the concrete slab. Untreated concrete typically begins to degrade at temperatures above 570 degrees Fahrenheit.